About

- Home

- About

What We Do

Why it Matters

Global temperatures are rapidly rising because of increasing levels of greenhouse gas in the atmosphere.

CO2 is the primary greenhouse gas responsible.

Humans put nearly 40 billion tons of CO2 into the air every year.

It’s our job to remove it.

Mosaic is building a cleaner future for people and the planet.

According to the latest report from the International Panel on Climate

Change (IPCC), we must halve global greenhouse gas emissions by 2030

in order to avoid catastrophic global warming of +1.5ºC. To do this,

corporate and global leaders must take advantage of the variety of

carbon-reduction solutions available — from switching to alternative

fuels to investing in carbon-dioxide removal (CDR) technologies — to

reduce new and existing CO2 emissions from the atmosphere.

Direct air capture is a leading carbon-reduction solution because of

its many benefits:

Versatile: DAC plants can be located anywhere in the world

because CO2 levels in the air are similar everywhere in the

world. Hot or cold climates, low or high elevations, close or far

from emission sources—DAC facilities are extremely location versatile.

Efficient: Generally, DAC plants require less space and land usage than other carbon-reduction solutions. On a land area of

less than 0.5 acres, Mosaic’s commercial DAC system can eliminate

10,000 tons of CO2 from the air every year.

Scalable: DAC systems are highly modular, designed so that a

single CO2 filtration unit can be stacked (like blocks) and

assembled into virtually any size to achieve megaton-CO2

capturing capacity.

Measurable: DAC systems make it easy to accurately measure and

track how much CO2 is captured.

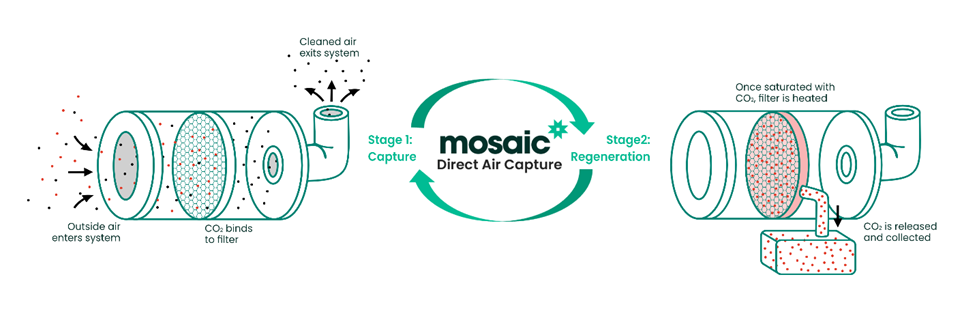

How it Works

1. Contaminated air in : Energy efficient fans pull CO2-rich air

directly from the atmosphere into the Mosaic DAC system.

2. Filter : Our proprietary filters, powered by a patented Metal

Organic Framework (MOF) technology, selectively bind and capture

more than 90% of the CO2 in the air that passes through the

system.

3. Clean air out : Filtered air exits the system and returns to the

atmosphere with drastically reduced levels of CO2.

Sequestration

Utilization

Utilization is when captured CO2 is recycled and used as an ingredient in a manufacturing process, such as that of food and beverages, building materials, chemicals, fuels, or fertilizers. Utilization can range from a carbon-neutral process when used in products like beverages that quickly re-release the CO2 into the air, to a carbon-negative process when used in products like concrete or plastic that sequester the CO2 in the material for decades. Either way, it recycles existing CO2 rather than introducing new, additive CO2 into manufacturing processes.

How It’s Different

Our Team

This is Us

Manufacturing and Materials

Engineering

Operations

Join the team who keeps our business moving forward.